Production Capability

Coligh Optics can handle the complete technology chain from extremely short wavelength (EUV) to long wave infrared (LWIR).

Including: EUV for semiconductor lithography high precision multilayer film reflector manufacturing

200-700nm (UV-visible band): anti-reflection film, high reflection film, multilayer dielectric film optical filter, spectroscopic film

700-2000nm (near infrared-short wave infrared band: anti-reflection film, high reflection film, communication filter, polarization spectroscopic film

3000-30000nm (mid-far infrared band: anti-reflection film, metal high reflection film, multilayer dielectric bandpass filter, protective film

Material processing diversity:

ULE, Zerodur, Sic fused silica, calcium fluoride, magnesium fluoride, Bk7, K9, Float Glass, B270, Color glass, silicon, ge, zinc selenide, zinc sulfide, AI2O3 sapphire, germanium, molybdenum, diamond, barium fluoride

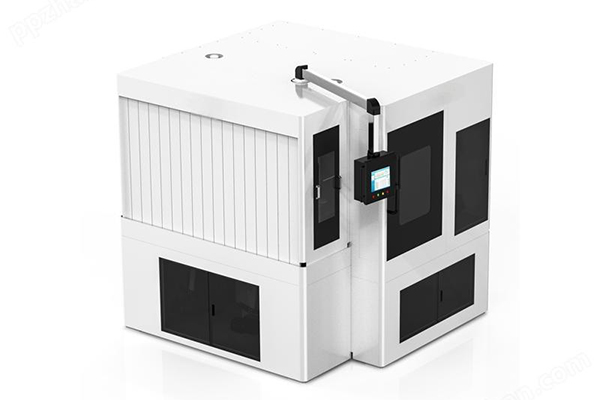

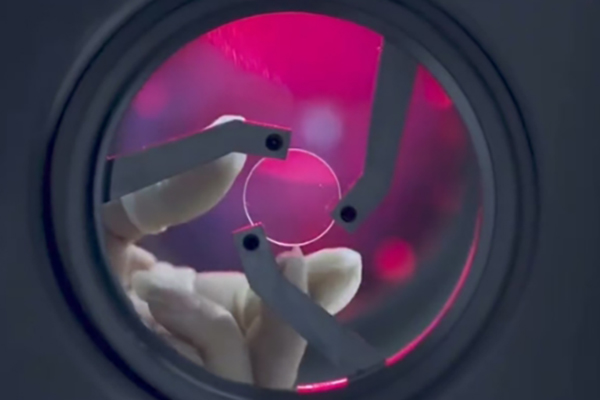

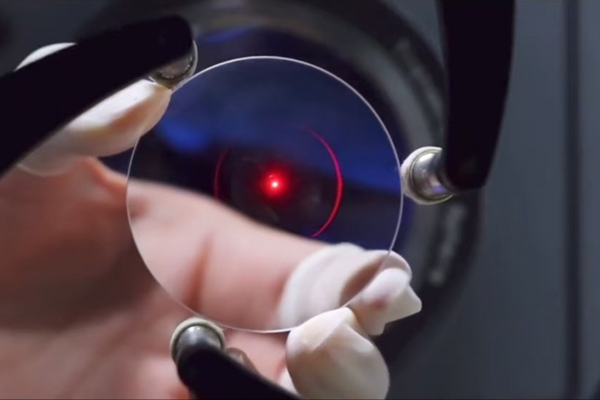

As a technology leader in the field of optical coating for many years, Coligh has always been committed to providing customers with high-precision, high-reliability, full-band coating products and services. We use advanced processes such as magnetron sputtering, ion beam sputtering (IBS), ion-assisted coating (IAD), electron beam evaporation (EBE), thermal evaporation, etc. to provide customized coating solutions for optical systems in the ultraviolet, visible light, near infrared to far infrared (EUV-30000nm)

We are specialize in utilizing different thin film coating techniques:

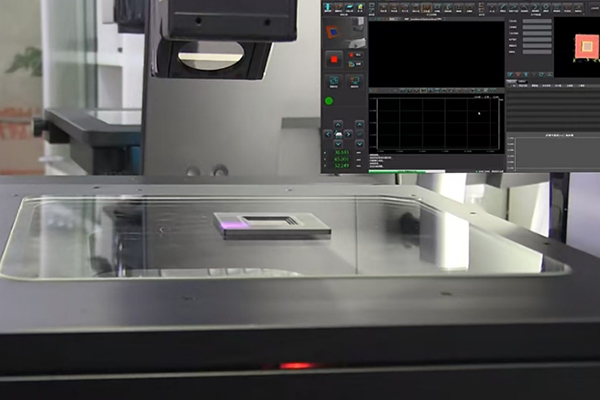

* Magnetron sputtering coating

Magnetron Sputtering is a common method used in the production of optical filters, and it offers several advantages over other coating methods. With sputtering, the thickness of the coating can be controlled down to a few nanometers, allowing for highly accurate and consistent coatings thickness. It also can produces coatings that are highly uniform, both in thickness and in composition.

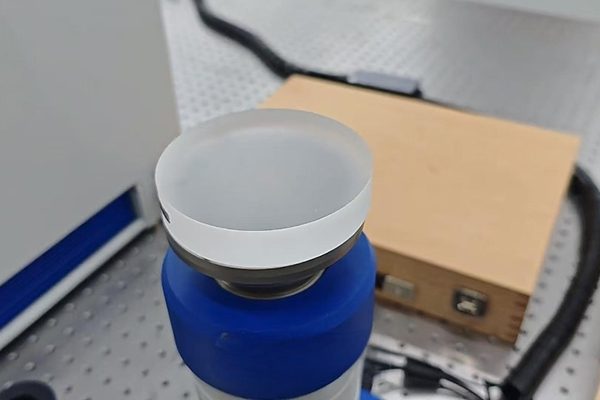

Ion beam sputtering coating

Ion sputtering can produce highly dense, uniform, and highly adhesive films. By precisely regulating the film structure and materials and controlling the sputtering conditions, multilayer films with low reflectivity, high transmittance, and high reflectivity can be obtained, and light of other wavelengths can be blocked. In high-end optical systems, ion sputtering can also be used to manufacture multilayer film filters by carefully selecting light of multiple wavelengths.

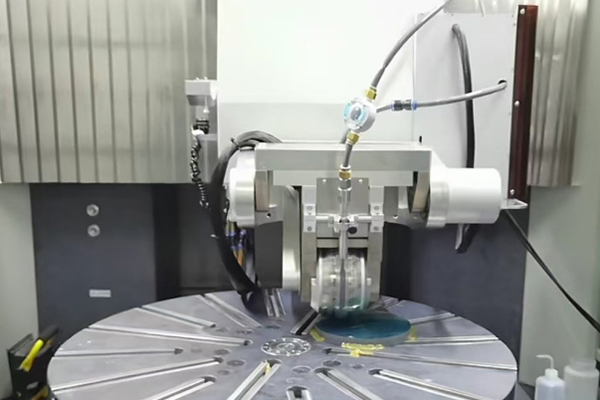

* Ion Assisted Deposition (IAD)

IAD( Ion Assisted Deposition) coating is another hard optical thin film coating technique Coligh applied. IAD is a technique that involves using a high-energy ion beam to bombard the substrate during deposition, which help to compress and density the coating, resulting in a stronger bond between the coating and substrate.This process provide a better better adhesion to the substrate. It also can improve durability of the optical filters and Enhanced optical performance:

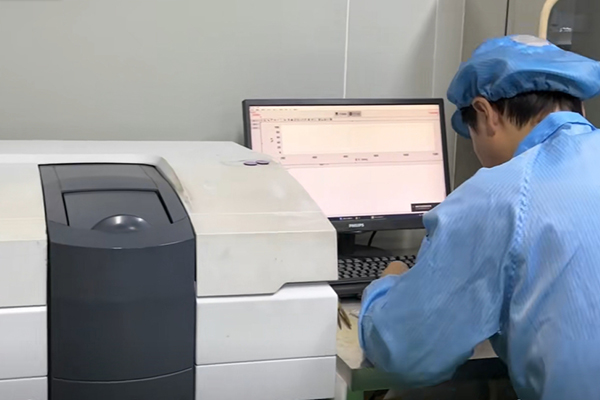

* Electron Beam coating

Coligh mainly uses Electron Beam coating to coat some laser optical components. It can provide coatings with high hardness and high laser damage threshold, thereby ensuring the stability and durability of laser components.

* Vacuum coating.

Vacuum coating is a versatile technology that can be utilized to create a variety of filter types for different applications. For instance, longpass filters, shortpass filters, dichoric filters, and anti-reflection coatings may require less strict requirements, and therefore, we continue to utilize vacuum coating for these applications.